TOTAL GUARDING & ISOLATION PROJECTS

1.TOTAL GUARDING PROJECT

2.TOTAL ISOLATION PROJECTS

Also see: SAFETY ISOLATION LOCKOUT SYSTEMS

Note: Vertical integration between the above subjects provides a safer management system

TOTAL GUARDING PROJECTS

Total guarding project proposal

Total Guarding of the machinery project for a Site

What we would be proposing:

Commit to the upgrading of the guarding and electrical safety interlocks on the existing equipment.

This work includes hazards assessment of the motors, hydraulic and pneumatic actuators that power the machine’s moving parts and assigning a CAT rating in line with AS 4024 and design of the appropriate controls. The control philosophy is to allow the operator to stop the part of the machine that he wishes to access using normal controls. The operator would then verify that the machine is safe to enter, open an isolator and fit his personal lock. This action will release the electromechanical lock on the guard. Secondary protection is provided to detect if the guard lock is overridden.

Why it would be proposed:

Known incidents including the near miss and injuries i.e. SSO.

The proposal is to address root causes in all of the incidents. The back-ground history of when the machinery was installed in at the site. The additions and modifications to the machinery over the years. Rapid changes in electronic technology will continue to generate needs to regularly review control hardware and software.

The machine may have many interlocked guards installed and these may have been upgraded on an ad hoc basis to cover more and more of the machinery over the a few years.

The machine may be complex to set up and with significant operator interaction with the machine. The incidents may have identified that the current guarding interlocking and isolation systems are inadequate in that:

- Guarding Interlocking may be predominately controlled via conventional PLC input and does not comply with Australian Standards for electronic safety control.

- Interlocking architecture interferes with efficient set up and operation of the machine to such an extent that approved variations to Companies’ Code of Practice are required to enable normal operating.

- Current isolation methods are incompatible with efficient set up practices.

The benefits:

The number of operational conditions would be assessed and risk ranked. The highest risk will be reduced to less than 4.0 at completion of the project.

Financial benefits will be calculated from the costs of SSO’s

The background

The current machinery assets requires the guard system to be upgraded to AS 4024.1-2006

The machinery has been assessed and a number of reports tabled.

The reports could be complied by the Lead Mechanical Engineer for the company

From the review by an assessment team i.e. Managers and supervisors.

Or by an assessment of all the tasks observed by the safety engineer i.e. an each task risk assessed both production and maintenance tasks.

The tabled information would be:

- Machinery operational access review – report & recommendations

- Hazard identification risk assessments:

- Entry area

- Processing area

- Exit area

- Variation approval forms: for total machinery

- Entry area

- Processing area

- Exit area

- Machinery operation access task matrices

- Entry area

- Processing area

- Exit area

- Operational access isolation matrices

- Entry area

- Processing area

- Exit area

Funding

Could be based over a period and on a capital application of $

Labour $ (65%)

Goods $ (25%)

Inconveniences $ (10%)

Note: Goods & labours estimates would be via spreadsheet

The expertises

Engineering persons with previous Guarding system design & implementation experiences will complete the project.

The Prerequisites for the persons are:

- Engineering experience with AS 4024.1-2006 Series : Safety of machinery

- Engineering background i.e. design drafting and engineering, both electrical and mechanical Site inducted

Basic knowledge of site and process

Has been trained in Protected person, Isolating person, Isolation planner and is an advanced contractor controller.

The plan

The plan would be based on working from the recommendations of tabled reports

An electrically intergraded system complimented by some mechanical guards would be designed and installed on the production line.

Design

- Electrical integration with the existing system must beplanned and achieved.

- Reference to standard AS 4024.1-2006 and operator &supervisor involvement will be key to the design.

- External specialist guarding knowledge would be sort from commercial suppliers of goods and services.

- Modification control would be via modification control system

Other milestones:: Building, Cold commissioning, Installation, Hot Commissioning, Documents, Training of personal, System maintenance.

Not considered is the Total isolation of any assets, this would be subject to a separate project plan

TOTAL ISOLATION PROJECTS

A proposal total isolation system for a site would consider the following points:

The background

The industry & current site’s assets that require the Total isolation system

The expertises of an experienced isolation systems person

An engineering person with previous Total isolation system implementation experiences will complete the project.

The project plan would consider and address

- Total Asset list review

- Review of each asset

- Isolation points

- Total isolation plans

- Listing of Registered total isolation plans

- Review of production tasks, frequency and duration

- Review of maintenance tasks, frequency and duration

- Isolation matrixes

- Listing of Registered Isolation matrixes

- Training of personal

- In the isolation system and isolation lock system

- System maintenance

Not considered is the Total guarding of any assets, this would be subject to a separate project plan

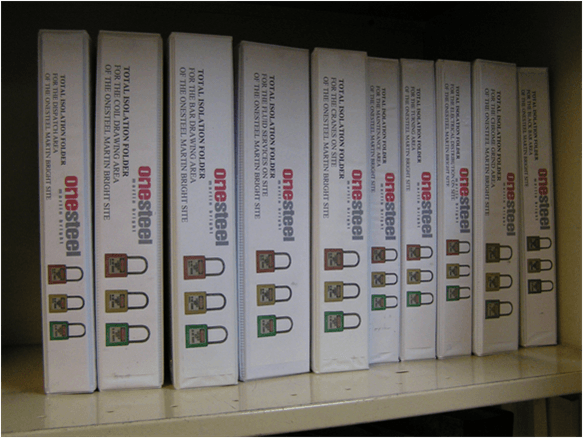

Example: Library of Total isolation plans, location of isolator plans and isolation matrixes using the safety isolation lockout systems