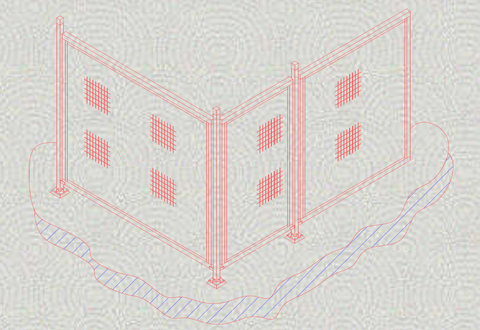

FIXED SAFETY FENCING SYSTEM

1. FIXED SAFETY FENCING SYSTEM

2. COMMON GROUP OF OPTIONS

3. DESIGN FEATURES

4. ACCESS CHECKING SYSTEMS

FIXED SAFETY FENCING SYSTEM

Managers, engineers and safety officers of manufacturing companies are asked by the Work cover Authorities to produce safety maps for their site.

From the safety map, the site personal are to produce plans, time lines and release resources to address on site hazards.

A common recurring scenario can be seen.

Most existing production safety problems are as follows:

I have a production line or machine that has a number mechanical hazards.

When the operator uses the machine, he is exposed to a risk and the likelihood of an accident.

The severity types of injuries that may be incur range from: bruising or lacerations to amputation or death.

FIXED SAFETY FENCING SYSTEM

Common Group of Options

The antonym of the word accident is design.

A common group of options present themselves.

The existing production safety answers are as follows:

Option 1

Remove the hazards or the person by re-engineering the process.

The answers are subject to investigation.

Option 2

Contain the hazards locally.

Design, build, install and commission a number of custom guards, this would be a cost restrictive and lengthy exercise in most cases.

Option 3

Contain the hazards within the machines boundary.

Commercially available perimeter guards are a cheaper and shorter lead time option. Perimeter guarding combined with a suitable access checking system reducers the likelihood of an accident by reducing the frequency or exposure time to the hazard.

Perimeter guarding combined with a suitable access checking system reducers the likelihood of an accident by reducing the frequency or exposure time to the hazard.

FIXED SAFETY FENCING SYSTEM

Access Checking Systems

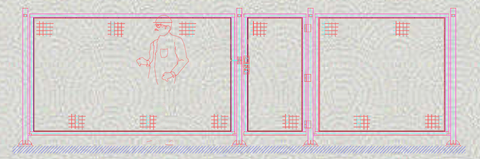

DESIGN FEATURES OF FIXED SAFETY FENCING SYSTEM

Complies with Australian Standard

Safeguarding of machinery Part 1: General principles

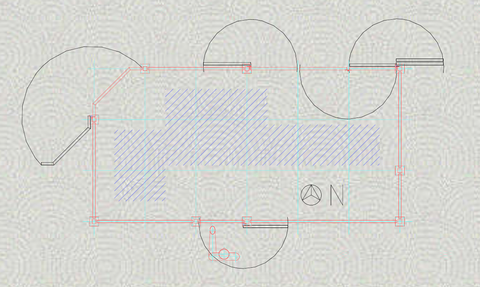

Each site layout is engineered to best suit the needs of the operator, production line or machine and the product.

Close fitting – within 100mm.

No nip points.

Aesthetically pleasing.

Clear visual access to operation of a production line or machine.

Safety yellow colouring of main columns and frames of panels.

High strength when installed and when disassembled.

Short installation lead times.

Suited to flat and slightly sloping concrete floors.

Layouts easily modifiable and components reusable for future expansion.

Easy access for maintenance personal.

For high forklift traffic area, the design can be complemented by removable bollards.

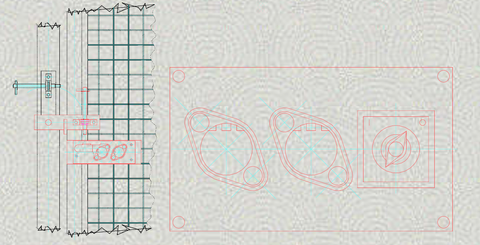

Existing various standard designs for access checking systems.

FIXED SAFETY FENCING SYSTEM

Design Features

A choice of access checking systems are available in the market place:

– mechanical interlocks

padlocks

captive-key interlocking device

trapped key interlocks

mechanical cam interlock

pneumatic/hydraulic interlocking

interlocking device with spring, applied/power release

– electrical interlocks

cam-operated switch

tongue-operated switch

start/stop manual control

plug and socket interlocking device

magnetically actuated proximity switches

two cam-operated switch

two proximity detectors

interlocking device with spring, applied/power release

light curtain

light scanner

pressure mats

A guide to choosing the right access checking system/s is to know the frequency of access required during the four phases of the machines operating cycle.

Please ring KEITH COSTER DRAFTING PTY. LTD. to discuss your companies needs for

FIXED SAFETY FENCING SYSTEM

on 04 25 81 61 61