CONTRACT ENGINEERING & DRAFTING SERVICES

— MECHANICAL DESIGN

— MECHANICAL DETAILING

— PLANT LAYOUTS

— COMPUTER AIDED DRAFTING

— COMPUTER AIDED DESIGN

— PRODUCT DESIGN

— TOOLING DESIGN

— SPECIAL PURPOSE MACHINE DESIGN

— PRODUCTION LINE DESIGN

— PRODUCTION AUTOMATION

— PROJECT ENGINEERING

— PROJECT MANAGEMENT

— SCHEDULING OF PROJECTS

— ESTIMATING OF PROCEDURES

— ESTIMATING OF COMPONENTS

— MECHANICAL REPORT WRITING

— PROCEDURE WRITING

— TENDERING AND PURCHASING

— SAFETY SYSTEMS & PROCEDURES

— FIXED SAFETY FENCING SYSTEM

— TRADES SUPERVISION

— DRAWING OFFICE SYSTEMS SETUP

— INCLUDING:

- CAD DRAWING CREATION

- CAD DRAWING MANAGEMENT

- CAD DRAWING ARCHIVING

PROCEDURES HAVE BEEN DEFINED TO ENSURE THE QUALITY OF ALL SERVICES.

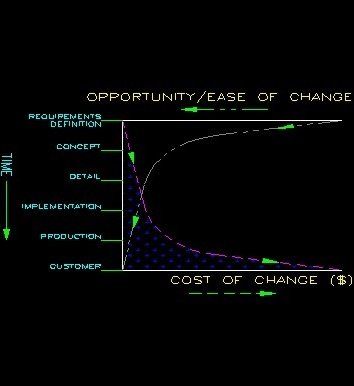

FULL ENGINEERING SERVICE –

“CONCEPT TO COMMISSIONING”

ALL WORK CAN BE COMPLETED IN OUR OFFICE OR ON SITE

ENGINEERED SOLUTIONS SUPPLIER

Engineered solutions supplied by analysing existing production methods with a fresh eye and the interviewing of the stakeholders.

Written suggestions of proposed solutions including ballpark cost and lead time estimations.

Design of engineered solutions using drafting techniques.

- CAD modelling to define the graphical scope of a job.

- Spreadsheet modelling to define kinetics, sequencing, and costing.

- Literal modelling to define the kinetics and sequencing.

Detailing of solutions

- CAD detailing of components, sub-assemblies, assemblies, machines and production lines.

ENGINEERED COMPONENT & SERVICES SUPPLIER

Component supplier:

Written budget costing of component supply (commercial and manufactured).

Manufacturing of engineered components:

- Machine shop work i.e. cutting, turning, milling, drilling, and grinding.

- Fabrication shop work i.e. cutting, welding, drilling and painting.

- Assembly shop work i.e. All facets of machine building, including pre-testing.

Installation work:

- Components, assemblies, machines and production lines.

Commissioning work:

- Assemblies, machines and production lines.

Ongoing maintenance of existing plant equipment:

- Day to day reactive maintenance.

- Shutdown work.

- Pre-engineered solutions for shut down work

ENGINEERED MANAGEMENT

Project engineering monitoring management techniques:

- Flow chart modeling to predict and follow sequencing.

- Spreadsheet modelling to follow and predict sequencing, and costing.

- Literal modelling to follow and predict sequencing and costing.

- Gantt and Pert chart modelling to follow and predict sequencing and costing.

- Archive management office documents including hard and soft files.

All services are offered on site and/or off site, which ever is most cost efficient.

Full project, “Concept to Commissioning and Servicing”, structured to suit the customers project size needs.